A very important part of building a garden room, no matter if a garden office, a summer house or simply a small storage room, is to make sure that the foundation is solid, strong and long lasting.

The traditional way to prepare the foundation for a building is using concrete, but, thanks to the continuous improving of technology, new ways are now available: Ground Screw, Screw Pile, Pads and concrete. All valid ways but here at A Room in the Garden we have opted for the Piling System.

There are several different good company selling screw piles in the UK but we have decided to go with UK Helix simply because their screw piles, in addition to be of a very high quality, can be easily adjusted in length depending by the size of the project and the kind of soil.

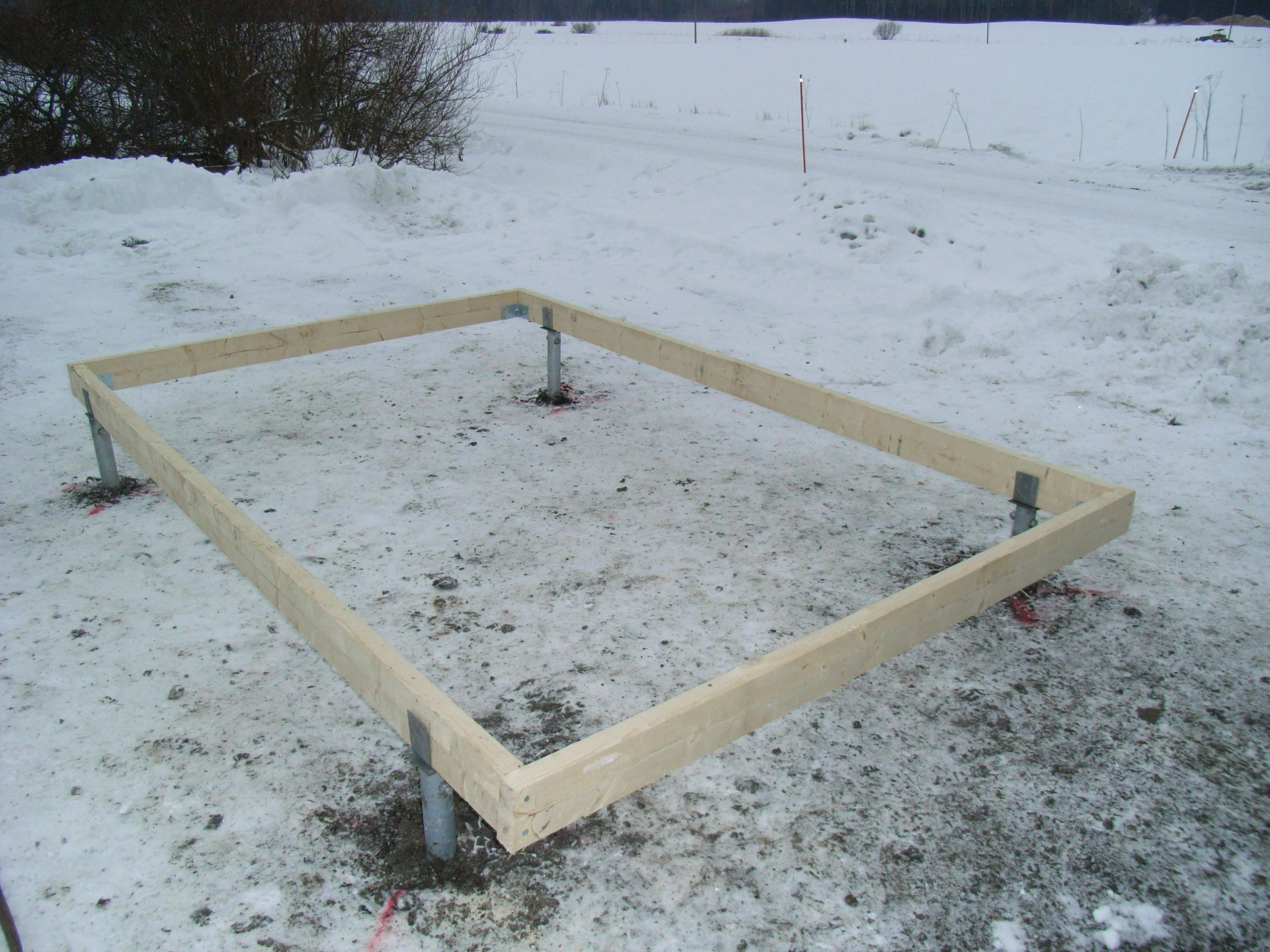

Paalupiste warehouse in Finland

I met with Rin Gamble, CEO of UkHelix, who very happily agreed to meet me for a coffee and answer all my questions.

I: Hi Rin. First, thank you very much to join me for a coffee. First question, as always, please tell us a bit more about your company, UK Helix.

R: Hi Ivana. The pleasure is all mine. Thank you for inviting me! UKHelix is an authorised sole distributor for Paalupiste screw piles, a leading quality screw pile manufacturer based in Finland. They have been designing and building screw pile since 2001 and they are considered a well-recognised and forward-thinking company. Always trying to improve their products and their offer. All the production is made in Finland to the highest standard and it is backed it up by an ISO90011 quality certificate and ISO 14001 environmental management certificate.

We are very proud to be their exclusive distributor in the UK!

I: The use of screw piles as foundations is well used in the Scandinavian countries, while here in the UK still seems to be a novelty. Is that correct?

R: Yes and no. The screw pile or piling system has been used in the UK for quite a long time now but mostly in the commercial constructions or in general in the construction of big building, which require a big excavation or where concrete is not a possibility. A perfect example is the Fishbourne Roman museum in Chichester. To preserve the Roman Villa a museum was built on top of the archaeological funds using the screw pile system. Also, a lot of projects in London are now done using screw piles due to the limited access, which makes it sometimes impossible for the concrete TIR to get there.

I: So, the novelty is that now screw piles are more and more used in the private sector and for smaller projects.

R: Yes. The screw pile system is getting more and more common. It is a perfect solution for garden rooms, fencing and elevated paths. But also, for houses and house extension. At certain scale, it is often cheaper, easier and faster and less messy than concrete. But not always. There are several options available now and what is good and more cost effective for one it is not necessary for another one.

I: One of the limitation of concrete is the weather. If it is too cold or if is raining the concrete can’t be applied. Is that the same for screw piles?

R: No. one of the many advantages of the pile system is that it can be installed with any weather condition. In addition, while with concrete you have to wait for it to set, with the screw piles you can start building straight away. Making the all process way faster!

I: How long does it takes to put a screw pile in the ground? And, will you do the installation?

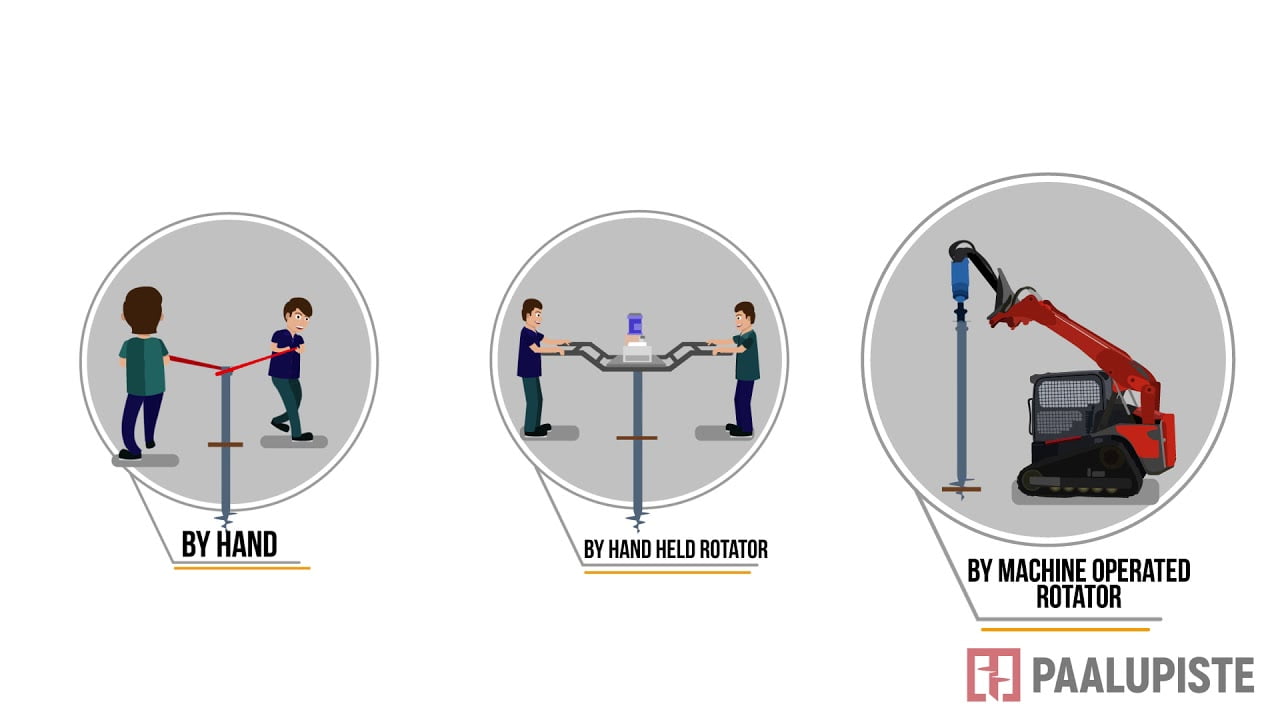

R: This is actually another unique point of our product. We can send our team to install the screw piles but in all honesty is so simple that anyone can do it. Especially if you take our installation kit (£12). I have tried myself with my husband simply using a crow bar and I managed fine! And, how you can see, I am quite petite! One screw pile will take around 10/15 minutes to install! And even less to unscrew it! And they can be reused!

Helix Screw Piles explanatory video

I: So, no more breaking the back to excavate the ground to prepare it for the concrete! No more breaking the back for taking the concrete away if you decide to redesign your garden!

R: Exactly! Pile screw are especially good if the new building is located on a slope! Instead of wasting time and energy excavating the ground to make it flat you can simply adjust the height of the screw piles. And job done! Our screw piles go from 70 cm to 3 metres long. And if 3 metres is not enough we have extensions that can be added.

There is no slope that we can’t tackle!

I: And what about if you hit a rock? Or a tree root, cable or a pipe?

R: Like any other digging job the ground has to be inspected to make sure that there are no cables or pipe. If you hit a rock, as when you excavate to prepare the ground for concrete, you can try to dig it out first. If that is not possible you can simply reposition your screw pile. In the unlikely situation that you hit another rock you can use a special drill which will go through it.

I: The pile system seems to be much more environmentally friendly than concrete.

R: Definitely. You do not disturb the vegetation at all!

I: Are the screw pile long lasting?

R: They will last forever! All other companies galvanise their product with a layer of around 80 to 100 microns. Our screw pile, including our cheaper range, has an average of around 200 microns. Technically, it takes 1 year to go through 1 micron… quite a simple calculation. And this is without considering the steel factor.

I: I have seen your screw pile. While the screw piles sold from other company have the shape of a giant screw yours have a smooth surface with a helical head at the bottom. Why is that?

R: To prevent any frost to get attached to the pile. In Scandinavian countries temperature often drops very low causing frosting. In any kind of foundation, you must consider the frost factor. If your foundation is above the frost level when the winter comes the water in the soil will freeze and expand. This will lift the foundation and cause the soil to move underneath. In summer time, the water will defrost and shrink back but the foundation will not be able to get back to its original position. We are talking of a lift of millimetres each time, but over time that will cause a problem to the whole construction. Because the smooth shape of our screw piles the water does not have a surface to get stuck to, preventing the formation of frost. The important thing is to make sure that the helical head is installed below the frosting level.

I: What about costs?

R: The price varies. As I mentioned before, every project is unique and we try to give to each client the best cost-effective solution. But as a guide line the price for a screw pile goes from 45 pounds up to few hundred pounds per set.

I: Thank you Rin for your time today. After our chat I feel even more confident about the pile system.

R: Right! It is faster, It is cheaper, It is cleaner

It is more environmentally friendly and it can be installed in minutes under any weather conditions